Morphological Diagram

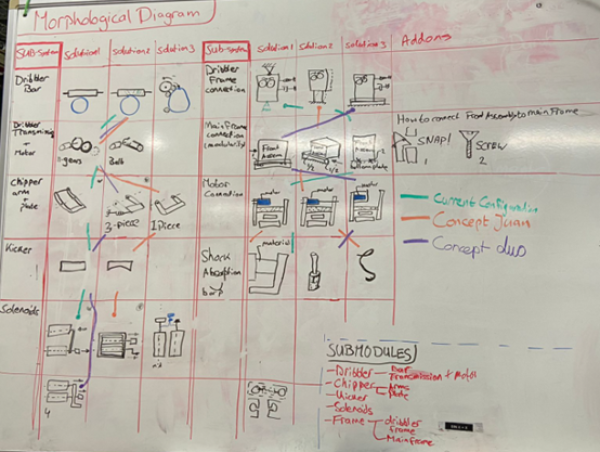

The entire front assembly has been divided in separate subsystems. Each one has its own function. Different solutions have been found for each subsystem, these solutions have been put in the morphological diagram shown in the figure below.

By choosing one solution per subsystem, a new concept of the front assembly can be formed. In the figure above, the drawn lines from box to box show the solutions chosen for a specific concept. The green lines show the current design of the robot, and the orange and purple lines show two new concepts.

The following sections will present each subsystem with the different solutions found for each one. Also, there will be an explanation about which solution was chosen for each subsystem and why this solution seemed better than the others and the current one.

Dribbler Bar

Three options have been considered for the dribbler bar. The first option is to have a simple bar that will rotate and give backspin to the ball. The second solution is like the first but it has a thread on the surface of the dribbler in order to center the ball, which is the solution currently being used. The last option consist of two smaller dribblers that are placed higher compared to the first two solutions. A third roller is added at the bottom, at the place where the chipper plate currently is.

The chosen dribbler bar is the one already being used. The current dribbler works well and is able to center the ball. However, the material used for the dribbler seems to wear off quickly which makes it loose its centering capability. Therefore, we will try to find a different material for it. Moreover, the profile on the dribbler works fine but can be improved by making the threads closer together. Finally, due to the fact that the dribbler motor is only fixed on one side of the front assembly, it sometimes falls onto the dribbler which makes it wear off even faster, so this needs to be prevented too.

Dribbler Transmission with Motor

For the transmission of the dribbler motor to the dribbler, there are two solutions that have been considered. Transmission can be done using toothed gears, as it currently is, or using a belt. The gears ensure reliable transmission if they are well aligned. The belt would allow us to place the dribbler motor a bit further away from the dribbler. Though, it would be important that a timing belt would be used for transmission to prevent slip.

The transmission between the motor and the dribbler will remain the same since it works well. The gear ratio is fine and the height of the dribbler was calculated such that the ball would touch the dribbler, the chipper plate and the ground when a robot catches the ball, which helps the robot catch and keep the ball more easily as explained in ZJUNlict's 2019 TDP. The belt was not chosen because it is difficult to find one small enough for this (this was looked into during the first RTT year) and the motor doesn't need to be further away from the dribbler therefore a belt isn't necessary.

Chippers Arms and Plate

The design of the chipper arms depend on the solenoids that will be used in the robot. If the chipper will still be actuated by a pulling solenoid, then the first solution has to be used. If the new solenoids can be implemented in the design, either option two or three can be used. Both work similarly, but option three will be made out of one piece of sheet metal.

As explained above, if new solenoids are used, the chipper will differ from the current one because the chipper plate will be pushed by a solenoid instead of pulling the chipper arms. Therefore the long chipper arms will not be needed anymore, they will just need to be long enough to be attached to the side of the front assembly. Also, they will be made of one flat piece of metal where the chipper arms will be bent to be put into place. Since currently the chipper arms are parts that often break, it might be beneficial to make them out of one piece. This might be less prone to break since no screws are involved in this design of the chipper.

Kicker

Different shapes of the kicker are considered. It is currently rectangular. If the ball is centered in the middle of the robot, the kicker will make sure that the ball will be shot in a straight line in the direction the robot is facing to. However, when the ball is not exactly centered, the direction of the ball will not correspond with the direction of the robot and will be rather unpredictable. Experimenting with different shapes for the dribbler might help to compensate for this unpredictable behavior in case the ball is not exactly centered.

The kicker will be slightly curved instead of straight. In the current design, if the ball is not centered, the kicker will kick the ball to the side instead of straight. With a curved kicker, even if the ball is not centered, the kicker should still kick it straight. This still needs to be tested to make sure it actually works.

Solenoids

Currently, we have two solenoids that are used to actuate the kicker and the chipper. The pushing solenoid for the kicker is located on the bottom plate and the pulling solenoid for the chipper is located on the middle plate. In 2020, a RTT mechanics' person started working on making new solenoids with the goal of having both between the middle and bottom plates in order to save some space in the robot, and for the team to be able to produce their own solenoids instead of having to buy off-the-shelves ones. Both solenoids would be pushing solenoids, which would change the chipper mechanism. If the pulling solenoid in the current robot can be changed into a pushing solenoid, then the chipper mechanism will have to be changed in the robot. This has been displayed in the morphological diagram as option four. Option three would be to locate both new, smaller solenoids on the bottom plate next to each other. However, since the kicker still needs to be in the center in order to shoot the ball in the right direction, some extensions for the kicker and the chipper would be required. Option two has the kicker solenoid on top of the chipper one, both would be enclosed in the same structure which would be located between the middle and bottom plates. Option one is the current configuration.

The chosen solution is option two, meaning two pushing solenoids, one on top of the other, both on the bottom plate. These solenoids are much smaller than the current ones and leave the middle plate free. They are currently being tested and improved in order to make sure they work at least as well as the current ones.

Dribbler Frame Connection

These options are the same as the ones mentioned in the Conceptual Design section of the front assembly redesign.

At first, the leave springs option was chosen for the dribbler frame connection. However, when looking into it more and trying to find ways to implement it while keeping the front assembly modular, it turned out that it was not the easiest option. The leave springs would have to be put under the dribbler and motor dribbler frame but then buckling would become a problem. Putting them on top is not any easier since there is very few room for them there. And some space was freed behind the front assembly but using the leave springs would not use that space. Therefore, the translational mass-spring-damper solution was chosen since it makes use of the freed space behind the front assembly and does not require to free some space above or below the front assembly.

Mainframe Connection

The mainframe needs to be fixed at all times on the robot, but should be able to be taken out easily if necessary. As already briefly described previously, it would be an option to guide the front assembly back and forth by means of rails. Snap fits could be used to keep the front assembly in place during riding. Another option would be to make some sort of outline of the front assembly which would be fixed to the bottom plate. The front assembly can fit in this outline, which will prevent it from moving sideways. The middle plate should prevent it from moving up. Option three is using screws to fix the front assembly. This might not be the most modular solution, but it does not involve a complex design and is reliable.

Option two was chosen, which is a U-shaped structure screwed on the bottom plate. The front assembly will be able to slide in between the inner sides of the U. We still need to measure how much friction there will be between the U-shape and the front assembly to make sure it won't slide out when the robots drive.

Shock Absorption

For the front assembly's damping, different combinations of solutions can be used. Firstly, some material with a dampening behavior can be placed behind the front assembly. It should be investigated which material would be suitable for this and how it will be connected to the mainframe and the front assembly. A second option is to use plungers. If these are off-the-shelf products, they will be very reliable and consistent over the different robot. However, it might be challenging to find plungers that are small enough for our front assembly. If leaf springs are included in the design, their natural damping might already damp enough and no extra mechanism will be needed to absorb the impact of the ball.

Natural damping as well as damping at the back of the front assembly will be used. The material that will be used is not known yet. The damping will not be connected to the U-shape.