Design Rationale 21-22

Modular Design

At the beginning of our year, after talking to mechanics from previous years, we learned that the parts which break most often in our robots are located in the Bottom Assembly. However this is the part that takes the most time to access, and we only have five minutes during games to repair robots. Therefore, we decided that we needed to redesign the robot in order to get access to these parts more easily. To do so, we have decided to design our robots in a modular way. Another team that used this approach is TIGERs Mannheim, their design can be seen in their Team Description Papers.

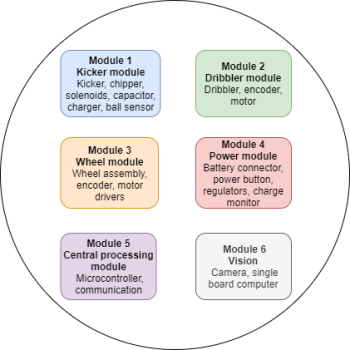

Therefore, we put the components and functions which belonged together in modules, as shown in the figure on the right. However, changing to a completely modular design in only one year is very ambitious, so we have decided to only make several parts modular for this year and leave the other parts for the teams of the next years. Therefore, this year we will mostly focus on making the front assembly modular since it is the part that breaks the most. Also, the solenoids' redesign started last year in order to get them to take less space in the robot, so this year's mechanics team will be working on this too.

Several other small changes will be made this year. For example, the PCBs on top of the robots vibrate when they drive which causes the PCBs to disconnect from the backboard and break, so this needs to be fixed. Also, the electronics sub-team aims to redesign the PCBs and move them to different parts of the robots according to the modular design plan, so the top assembly will eventually need to be modified in order to take these changes into account.

More detailed information on the design changes is separated in the different components: