Second Iteration

By taking into account the problems encountered in the first iteration of the front assembly, as well as by keeping in mind the things that did work as expected in the first design, we came up with a new design for the front assembly.

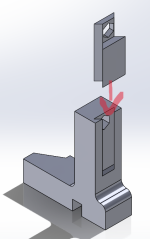

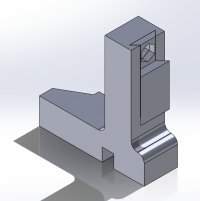

The structure built to support the dribbler motor worked really well so this part was not modified. The locking mechanism also worked as expected so they will not be changed. The main problem with the first iteration was the shock absorbers which were too big. They were also complicated to build and could not be produced at the RTT office. Therefore, it was decided to look into putting some material as damping like it is in the current design, or to 3D print the dampers. Keeping in mind that an important issue with the current dampers is the way they are attached in the front assembly, so we need to come up with a way to be able to remove and fix the dampers easily. For example, we can fix the damper on a 3D printed part which can be slided in the front assembly as shown in the figures below.

Another problem encountered was the friction between the front assembly and both the bottom plate and the main frame. A solution to this problem is to put ball bearings under the front assembly to reduce its friction with the bottom plate, and to put ball bearings on the main frame in order to reduce friction between the front assembly and the main frame. Finally, there were some issues with the back parts of the front assembly. However, these parts need to be modified since the damping mechanism will change. They are expected to be closer to the front, since the damping will not be as big as the J-dampers, therefore the problems encountered with them will not be a problem anymore.

By taking all these new solutions into account, we made a new solidworks design of the front assembly. This design did fit properly in the robot, it was modular and fixed the problems encountered in the first iteration. However, it still had some major issues which needed to be fixed. First, the main issue was already there in the first iteration, however we had not thought of that until now. This issue is the fact that the ball does not only have a horizontal force but also a vertical one which needs to be taken into account. Therefore, having the front assembly only move horizontally is not a good idea. Moreover, this new design takes a lot of space on the bottom plate. It is a problem we only encountered recently because the solenoids are also being redesigned at the same time as the front assembly and they need to be placed on the bottom plate. Therefore, to be able to fit both the front assembly and the solenoids on the bottom plate, it is necessary to have a front assembly that does not take too much space at the back. Finally, with the ball bearings the front part of the front assembly could easily slide out of the robot which is not something we want to happen during the games.

Therefore, a new design of the front assembly needs to be made by taking these issues into account.