Bottom Assembly

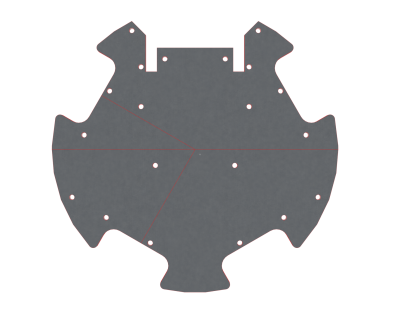

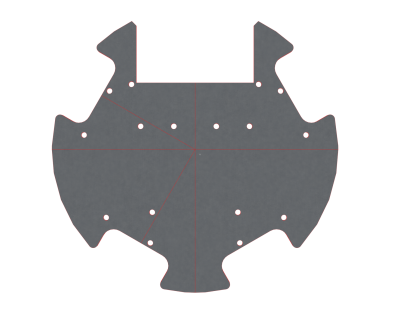

The bottom plate had to be modified in order for the new solenoids and front assembly to be attached to it properly. Indeed, they did not have the same dimensions as the previous front assembly and solenoid, so new screw holes had to be added in the bottom plate. Also, the front assembly is wider so the cutout in the front of the plate had to be made bigger. Finally, most holes that were there before had to be removed, only the ones for the motor mounts have not been changed. The figures below show the old and new bottom plates on the left and the right respectively.

This new bottom plate was manufactured by the same company which made the motor mounts. Therefore, it was necessary to make a drawing of it, which can be seen here. For more information about how to make a technical drawing click here.