Front Assembly

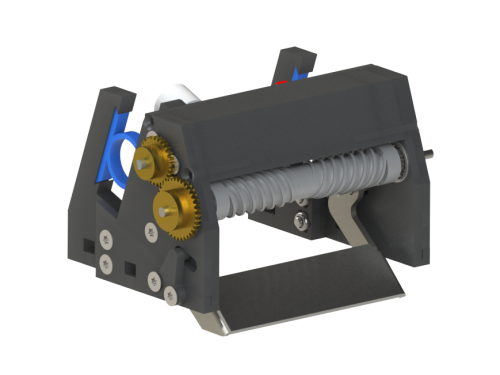

The front assembly is connected to the bottom plate using four screws and is responsible for receiving, dribbling, and chipping the ball. It is made of a dribbler assembly, a damping mechanism and a chipper.

The front assembly is connected to the bottom plate using four screws and is responsible for receiving, dribbling, and chipping the ball. It is made of a dribbler assembly, a damping mechanism and a chipper.

The dribbler motor (Maxon motor) can be placed in the bridging part of the front assembly, it fits exactly in there. There is a hole in the back for the motor cable and encoder cable of the dribbler motor. The dribbler itself can be placed in between the left and right moving parts of the front assembly. The dribbler was made using a mold and it is made of a mixture of silicon caulk and cornstarch called oogoo. It has a thread on it to be able to bring the ball to its center when the robot is dribbling. The gears are made of brass and the transmission from the motor to the dribbler works well as long as the gears are well aligned. Here are the details about the small and the big gears.

The damping is done by the two blue circular parts at the back on the assembly, as shown in the figure. These parts have been made out of Ultimaker blue TPU 95A. We can print these parts ourselves on the Ultimaker S5 printer, so these parts are all very similar. Therefore, the damping behavior is very consistent over all robots compared to the 20-21 design. Also, the damping behavior can be changed easily by increasing or decreasing the thickness of the parts. The parts can be easily slid in between the moving and the static parts of the front assembly.

During 2022 - 2023 the side panels had been modified to add mountings for the new chipper plate.