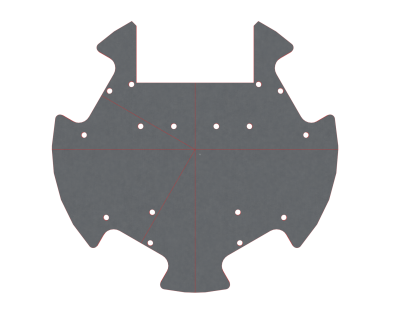

Bottom Plate

The bottom plate is located at the bottom of the robot, it is connected to the middle plate by means of the four motor mounts. The front assembly, the solenoids and the four wheel assemblies are connected to it.

The bottom plate is located at the bottom of the robot, it is connected to the middle plate by means of the four motor mounts. The front assembly, the solenoids and the four wheel assemblies are connected to it.

The bottom plate is made of AISI 304 (1.4301), a widely-used austenitic chromium-nickel stainless steel which is highly corrosion-resistant. The bottom plates have been produced by an external company Leering Enschede. A technical drawing of the bottom plate can be found here. The holes for the screws are sunken at the bottom side of the plate. Because of this, the screws do not stick out which allows the robot to drive smoother. The cut out parts for the front wheels are at a 30 degree angle from the red horizontal line in the middle of the plate on the figure. The back wheels are at a 60 degree angle from that line. This placement of the wheels was tested in 2019-201) along with different wheel placements to see which worked best and the results of this test showed that this configuration is best.

In 2023 two extra holes have been added to allow for better mounting of the solenoid mounts. - Updated file availablehere.