Front Assembly

The front assembly is connected to the bottom plate using four screws and is responsible for receiving, dribbling, and chipping the ball.

It is made of a dribbler assembly, a damping mechanism and a chipper.

The front assembly is connected to the bottom plate using four screws and is responsible for receiving, dribbling, and chipping the ball.

It is made of a dribbler assembly, a damping mechanism and a chipper.

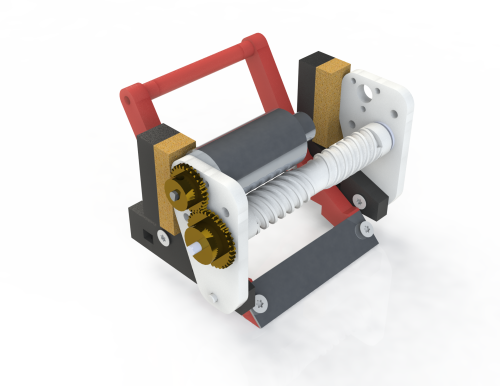

The dribbler assembly is connected to the two 3D printed PLA parts of the front assembly that move (in white in the figure) and it is made of a Maxon motor and a dribbler which are connected by two gears. The dribbler was made using a mold and it is made of a mixture of silicon caulk and cornstarch called oogoo. It has a thread on it to be able to bring the ball to its center when the robot is dribbling. The gears are made of brass and the transmission from the motor to the dribbler works well as long as the gears are well aligned. Here are the details about the small and the big gears.

The damping is done by two sponges put between the black and the white 3D printed PLA parts in the figure. The sponges are glued onto the 3D printed parts. The damping behavior is different for each robot since it depends on how the sponges were cut and how they were glued. Therefore some robots have good damping and others barely have any.

Finally, the chipper is connected to the black 3D printed parts with two screws. The chipper arms as well as the part connecting them at the back are 3D printed with PLA. The chipper plate is made of steel and is connected to the chipper arms with screws, but this connection is not very strong and so it breaks quite often.