Solenoids

Another important part which was recommended to improve by the mechanics of 20-21 was the solenoids. In fact, the ones of 20-21 were off-the-shelf, so they took a lot of space in the robot, and in the Small Size League it is important to make the components as small as they can be due to the size constraints (150mm height and 180mm diameter). Also, making new solenoids was recommended because we can have better control over their specifications, which makes it easy to make small changes to the solenoids in order to improve their performance. Finally, it is easier to fix or make new solenoids if we make them ourselves rather than buying them online and being dependent on a company.

Design Iterations

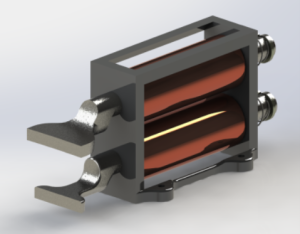

The design of the new solenoids was inspired by other SSL teams' designs. Therefore, we decided to have two cylindrical pushing solenoids on top of each other, both on the bottom plate. The following picture shows the first design made. In this design, the kicker is on top of the chipper solenoids, but this made the kicker too high which would have made it collide with the dribbler bar. Therefore, the next design was made with the kicker below the chipper.

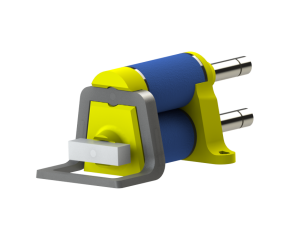

The second design iteration is shown in the figure below. As explained before, this time the kicker is below the chipper solenoid so that it is at the right height to hit the ball, and the chipper solenoid's plunger is attached to a grey plastic part which can push the chipper plate in order for the robot to throw the ball in the air. This configuration worked really well, but there were still some small issues. First, the white plastic part of the kicker can rotate easily, which would sometimes cause it to be vertical instead of horizontal after kicking. Also, the green plastic part that holds the solenoids was touching the motors at the back of the robot. Finally, the black plastic part of the chipper did not have enough contact with the chipper plate, which prevented the robot from chipping far enough. These issues were fixed in the final design.

The final design iteration of the solenoids can be seen in the figure below. The issues mentioned above were fixed. To prevent the kicker from rotating, a slope has been added such that it can go back to a horizontal position after kicking. Then the green plastic part at the back was made short to prevent it from touching and damaging the motors. Finally, the grey plastic part of the chipper was made bigger on the part that touches the chipper plate. Therefore, with the final design iteration of the solenoids, all issues that we found were fixed. The green plastic parts are made of ABS to make them sturdy enough to prevent them from breaking when the robot kicks or chips. The plastic parts attached to the plungers of the solenoids are either made of PLA or Tough PLA.