Conceptual Designs

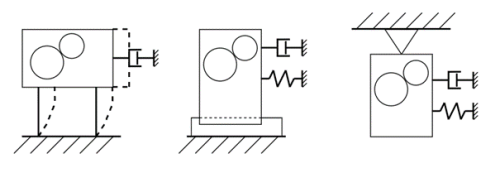

As of September 2021, the front assembly is damped by sponges and the dribbler frame is connected to the robot with a hinge that is prone to wear and causes residual play in the front assembly. To solve this problem, three different general concepts are proposed and shown in the figure below.

The first idea is based on a flexure design, using leaf springs to constrain the rotations and translations in undesired directions. Four leaf springs will be used in total, two on each side. There should also be some damping at the back of the assembly to absorb the impact of the ball and vibrations that might be present during driving since it is expected that the leaf springs will not damp out all vibrations. The leaf springs will be mounted to a piece that will be guided by rails on the bottom plate. In this way, it will be easy to take out the entire front assembly without having to disconnect the leaf springs from the rest of the assembly. A great advantage of incorporating flexures in the design of the dribbler assembly is that it would make the system accurate and resistant to wear. In general, flexure elements do not wear out, when designed properly, because there are no sliding surfaces, which means that the system requires low maintenance (in principle).

The second design is based on a mass-spring-damper system that can translate in one direction. The translational movement of the front assembly will be guided by rails on the bottom plate. These rails will also allow the assembly to be taken out easily. Though, it should be prevented that the assembly can slide out of the robot when driving. This could be done by blocking the assembly at the front or by using some clamping mechanism like snap fits.

The third design looks quite similar to the current design. Both use damping in the back and a hinge to enable small rotations. The main difference between this concept and the current design is that the hinge point is located at the top of the construction instead of at the bottom. The testing results showed that a hinge point at the top might work better than having the hinge point at the bottom. Making this design modular and easy to take out would require some kind of sliding mechanism on the middle plate instead of on the bottom plate.